Understanding the Different Grades of Steel

Posted by adminDemac Comments Off on Understanding the Different Grades of Steel Uncategorized

Understanding the Different Grades of Steel

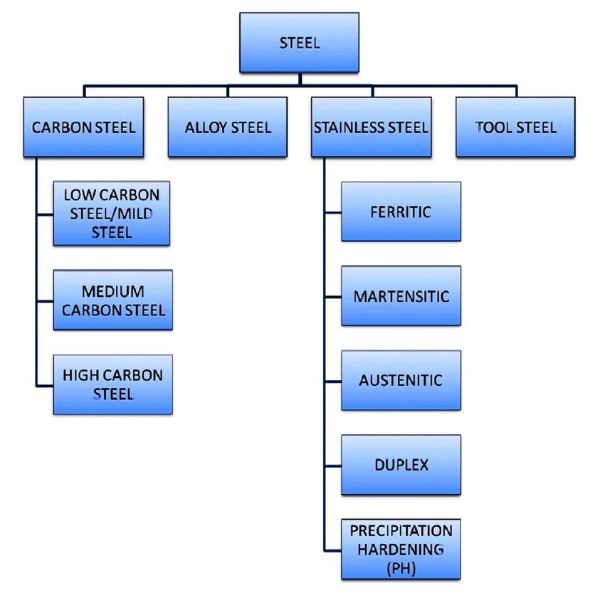

Steel is a versatile material with a wide range of applications, from construction to manufacturing and beyond. The specific properties of steel depend on its grade, which is determined by its composition and the processes used to produce it. There are variety of steel grades available in the market, each tailored to meet the unique needs of different industries and applications. In this article, we will explore the different grades of steel and their specific uses.

1. Mild Steel (MS)

Overview: Mild steel, also known as low-carbon steel, contains a relatively low amount of carbon, typically around 0.05% to 0.25%. It is known for its ductility, malleability, and ease of welding.

Uses:

- Construction: Mild steel is widely used in construction for structural elements such as beams, columns, and steel frames.

- Automotive: It is used in the manufacturing of automotive parts like body panels and chassis components.

- Pipelines: Due to its strength and weldability, mild steel is used in water and gas pipelines.

2. Galvanized Iron (GI) Steel

Overview: Galvanized iron steel is coated with a layer of zinc to protect it from corrosion. This process, known as galvanization, extends the steel’s lifespan, especially in environments prone to rust.

Uses:

- Roofing and Cladding: GI steel is commonly used for roofing sheets, wall cladding, and siding due to its corrosion resistance.

- Fencing: It is used in the production of fences, gates, and guardrails.

- Piping: GI pipes are used in plumbing, water supply systems, and outdoor construction projects where exposure to moisture is a concern.

3. High-Strength Low-Alloy (HSLA) Steel

Overview: HSLA steel is designed to provide better mechanical properties and greater resistance to atmospheric corrosion than carbon steel. It contains small amounts of alloying elements such as copper, nickel, and chromium.

Uses:

- Bridges: HSLA steel is used in the construction of bridges due to its high strength-to-weight ratio.

- Heavy Machinery: It is ideal for making parts for heavy machinery and equipment, where strength and durability are essential.

- Shipbuilding: HSLA steel is used in the construction of ships and offshore structures, where corrosion resistance and strength are crucial.

4. Tool Steel

Overview: Tool steel is a type of carbon and alloy steel that is particularly well-suited for making tools. It is known for its hardness, abrasion resistance, and ability to hold a cutting edge.

Uses:

- Cutting Tools: Tool steel is used to make tools like drills, saw blades, and punches.

- Molds and Dies: It is used in the manufacturing of molds and dies for shaping and cutting materials.

- Wear-Resistant Applications: Tool steel is used in applications where resistance to wear is important, such as in industrial machinery and equipment.

5. Stainless Steel

Overview: Stainless steel is an alloy of iron that contains a minimum of 10.5% chromium, which gives it remarkable corrosion resistance. It is also known for its strength, durability, and aesthetic appeal.

Uses:

- Food Processing Equipment: Stainless steel is widely used in the food industry for equipment that requires high levels of hygiene.

- Medical Instruments: It is used to manufacture medical instruments and surgical tools due to its non-reactive properties.

- Architecture: Stainless steel is used in modern architecture for exterior cladding, handrails, and decorative elements.

6. Carbon Steel

Overview: Carbon steel is composed mainly of iron and carbon, with the carbon content varying between 0.05% and 2.0%. It is categorized into low, medium, and high carbon steel based on its carbon content.

Uses:

- Automotive Components: Medium carbon steel is used in the manufacturing of automotive components like axles, gears, and crankshafts.

- Structural Steel: High carbon steel is used in the construction of buildings, bridges, and other infrastructure.

- Tools and Blades: Low carbon steel is used to make tools, blades, and other products where a balance between strength and flexibility is required.

7. Alloy Steel

Overview: Alloy steel is made by adding various alloying elements such as manganese, silicon, nickel, titanium, and copper to carbon steel. These additions enhance the steel’s properties, making it more suitable for specific applications.

Uses:

- Automotive Industry: Alloy steel is used in the production of engine parts, gears, and other automotive components due to its strength and wear resistance.

- Power Plants: It is used in power plants for parts that need to withstand high temperatures and pressures.

- Aerospace Industry: Alloy steel is used in the aerospace industry for structural components that require high strength and toughness.

8. Spring Steel

Overview: Spring steel is a low-alloy, medium-carbon steel with a very high yield strength. It is used to make components that need to return to their original shape after significant bending or twisting.

Uses:

- Springs: As the name suggests, spring steel is primarily used to manufacture springs, including those in automotive suspensions and mechanical devices.

- Locking Mechanisms: It is used in the production of locking mechanisms where flexibility and strength are required.

- Hand Tools: Spring steel is used to make hand tools that require flexibility, such as wrenches and pliers.

9. Maraging Steel

Overview: Maraging steel is a carbon-free iron alloy that is strengthened by a process called age hardening. It is known for its high strength, toughness, and malleability.

Uses:

- Aerospace Components: Maraging steel is used in the aerospace industry for components that require high strength and lightweight properties.

- Military Applications: It is used in the production of military hardware, including rocket casings and missile components.

- High-Performance Sports Equipment: Maraging steel is used in the manufacturing of high-performance sports equipment such as golf club heads and fencing swords.

10. Weathering Steel (Corten Steel)

Overview: Weathering steel, also known as Corten steel, is a group of steel alloys that develop a stable rust-like appearance after exposure to the weather. This steel is designed to resist corrosion without the need for paint.

Uses:

- Architecture: Weathering steel is used in building facades and bridges for its aesthetic appeal and durability.

- Outdoor Sculptures: It is popular in outdoor sculptures and installations due to its distinctive look and low maintenance requirements.

- Infrastructure: Weathering steel is used in the construction of infrastructure projects like bridges, where corrosion resistance and longevity are critical.

Conclusion

Understanding the different grades of steel is crucial for selecting the right material for your project. Each grade of steel has unique properties that make it suitable for specific applications, whether it’s the malleability of mild steel, the corrosion resistance of galvanized iron, or the high strength of HSLA steel. By choosing the appropriate grade, you ensure that your structure or product meets the required standards for performance, durability, and safety.

Recent Posts

- The Environmental Impact of Steel Pipe Manufacturing and Sustainable Alternatives

- Maintenance Tips for Prolonging the Life of Steel Pipes and Tubes

- Why Kerala’s Growing Infrastructure Demands High-Quality Steel Pipes and Tubes

- Steel Pipe Manufacturing Process: From Raw Materials to Finished Products

- The Benefits of Using High-Quality Steel Tubes in Industrial Applications

Archives

Categories

Recent Posts

Archives

Latest Projects

Do you have any questions?

At Demac Steel, we take immense pride in being recognized as the providers of the best Gp steel pipes in Kerala.

Contact Us